PVC Pipe Bow

Building and Testing Bows

Fiberglass bow

How to Build a 40 Pound No Heat PVC Bow for Less Than $7 - YouTube

Takedown bow:

Take-Down PVC Longbow Explanation - YouTube

Making a 38 Pound 3 Piece Red and Black PVC Takedown Bow - Compact Under 18 Inches - YouTube

- He uses Formufit PVC pipe

- As long as you do the hammer test, you probably don't have to worry about it,

- Mostly just adds color, and mught change the flexibility/etc. because of the additives in the color.

- For this bow, he uses red furniture grade Schedule 40 3/4" PVC for the limbs, and black schedule 40 1" PVC for the joints and handle.

- The handle is 4 1/8 inch long and the limb joints are 4 1/4 inch long

- He cuts the main bow in half for the handle and uses hot-melt glue to adhere it on both sides (which he pre-applied a little to each side of the riser before inserting)

- He uses what appears to be glue-gun hot-glue sticks for adhering the pipes together.

- He doesn't use a ton of it; just a little on the broadest side of the internal piece.

- To make the limbs easier to remove, he sands the limb inserts with 220 grit sand paper.

- Then he inserts the limbs, pulls them out, and checks if it has any parts that stand out or rub.

- He sands those down until they're smooth; you don't want it loose, but require some effort to disconnect.

- He also rubs down the inserts with a mix of bow string wax (mineral oil + bees wax) to reduce creaking from the limbs.

- He also marks the limbs with a dremel, adding two dots/grooves to one side, and one dot/groove to the other.

Adding a Fiberglass Bundle Core to PVC Takedown Bow - 38 to 63 Pounds - 160+ FPS Test and Giveaway - YouTube - In this video, he takes the red/black takedown bow and adds fiberglass rods, and increases the strength significantly.

- Rods are 37", 33", and 20" to provide the tapering

- The goal being the center rod sticks out about an inch once it's seated.

Bow Efficiency Testing

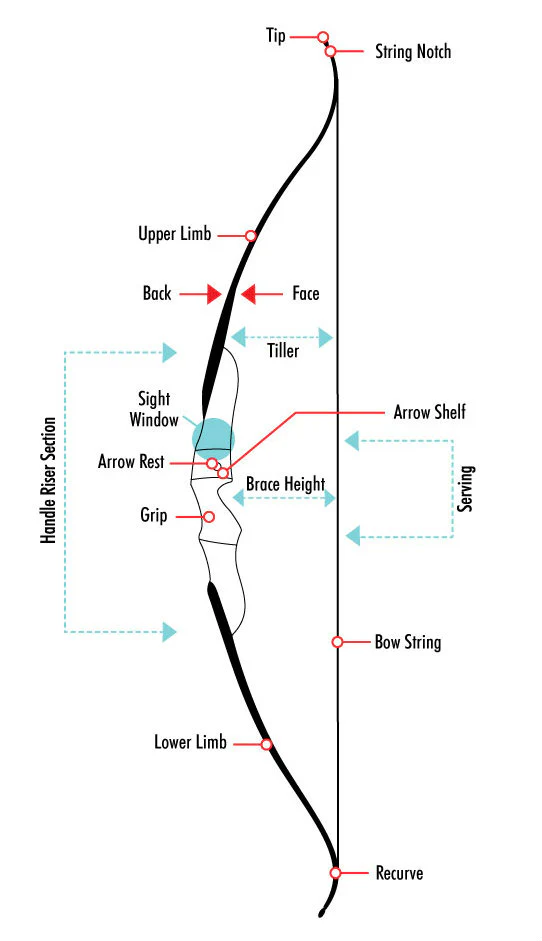

Recurve bow anatomy: A basic guide to the parts of a bow – Lancaster Archery Supply

Note: Brace height is also known as fistmele

| Pipe Width(s) | Bow Length | Fiberglass Rods | Brace Height | Draw Weight |

|---|---|---|---|---|

Determining Proper Fistmele

"A higher brace height helps reduce bow vibration and noise and also minimizes the effects of shooting errors. A lower brace height provides increased arrow velocity. Increased noise and poor arrow flight can be the result of a brace height that is too low."[1]

Brace Height | Archery Basics Explained - YouTube

"Below are some brace-height ranges. These guidelines work for most recurve bows, but always follow the manufacturer’s recommended brace-height range.

- 62- and 64-inch bows have 7½- to 8½- inch brace heights.

- 66- and 68-inch bows have 8- to 9-inch brace heights.

- 70- and 72-inch bows have 8¾- to 9½-inch brace heights."[2]